This time around, we shall cover Vinyl Plank Flooring Subfloor Prep. Obviously, there is a great deal of information on How should I prepare a plywood subfloor for floating vinyl plank flooring? on the Internet. The fast rise of social media facilitates our ability to acquire knowledge.

Best Subfloor For Vinyl Plank Flooring-related material is also connected to Best Subfloor For Vinyl Plank Flooring and Raising Subfloor For Vinyl Plank. As for further searchable items pertaining to Underlayment For Vinyl Plank Flooring On Concrete, they will likewise have anything to do with Preparing Subfloor For Vinyl Plank Flooring.

81 About Vinyl Plank Flooring Subfloor Prep | Do I need underlayment to install vinyl plank flooring?

- Rigid Click vinyl can be installed on irregular subfloors and makes subfloor preparation unnecessary in most cases. But we still highly recommend making sure the surface is dry, level, stable and clean. Remove all existing floor covering before getting started. Source:

Internet - Vinyl floors are a popular choice for most homeowners because of their durability, low maintenance, and easy installation. is a type of flooring that is popular nowadays. It’s usually made of polyvinyl chloride or vinyl, which are thermoplastic materials. The material is one-time used, making it more environment friendly. Source:

Internet - If the floor break takes place in an area other than under a door, I prefer to lay the first sheets along the floor break edge and work back into the vinyl area of the room. This allows me to cut and fit the smaller pieces against the walls and under the cabinet areas where the tolerances are less demanding. Also, if you start with a nice straight factory edge along a carefully established floor break it will greatly improve the transition between flooring types. Source:

Internet - Prepare the Floor Vinyl plank flooring can usually be laid right over existing flooring, but if there are any high spots, they should be sanded down to create a flush surface for the new floor. Your goal is to create the flattest, smoothest surface possible as the underlayment for the vinyl plank flooring. If you are laying vinyl plank flooring over a concrete subfloor, fill any cracks or divots with a concrete patcher. Source:

Internet - Floor breaks are where the vinyl meets the carpet (or whatever other flooring is adjacent to the flooring you are preparing to install on your underlayment). The edge of your underlayment is the place where the vinyl and the carpet meet. If, for example, you are installing vinyl in a bathroom, you will want to make the floor break under the door going into the bathroom. Source:

Internet - The rule of thumb is any vinyl over 4mm can have a vinyl specific underlayment. With thinner vinyl flooring construction, adding a foam underlayment can effect the locking system strength. Vinyl floors under 4mm should be installed right over the subfloor. If you have any areas on a concrete subfloor with moisture concerns, it is recommended to use a vapor barrier underlayment that will not add any cushion to the planks. Source:

Internet - Armstrong S-184 Fast-Setting Patch & Underlayment with water or S-194 Patch & Underlayment with S-195 Latex can be used for overall leveling of approved suspended wood underlayments, but are not recommended over stripwood floors. Both are Portland-cement based with a compressive strength of 4,500 psi (pounds per square inch) and can also be used over concrete, ceramic tile, quarry tile, terrazzo, and existing asphalt adhesive residue. Once spread, it is dry and ready for flooring installation in about one hour. Source:

Internet - The preparation process for installing laminate is pretty much the same as it is for hardwood subfloors. It needs to be cleaned and levelled off to ensure it’s going to provide a stable base. Moisture should also be kept to a minimum, ideally with a less than 12% moisture reading. Source:

Internet - Vinyl flooring is one of the most popular types of flooring in the USA. It is durable, easy to install, and has a great look. Vinyl floors are available in a wide range of colors and designs, but they require a subfloor that the vinyl can be laid onto. It is not recommended to install vinyl on top of concrete. Source:

Internet - Another common underlayment material is plywood, which has an advantage over particle board in structural strength and water resistance. One concern with plywood, as a walked-on surface, is that voids in the interior veneer layers may allow a depression in the flooring if weight were concentrated in one spot, such as a big ol’ girl wearing high heel shoes. I suppose that could happen, but it’s not likely. If this is a concern, marine-grade and underlayment-grade plywoods will avoid the voids. Source:

Internet - This flooring style comes with an adhesive layer applied by the manufacturer that allows you to connect your planks to each other. A byproduct of this installation method is that you have ultimately created a floating floor for yourself. The planks do not actually adhere to your subfloor in any way, shape, or form. Source:

Internet - AccessFloorStore is a B2B online yeloowpage Platform. we have earned resoueces about vinyl flooing local store and facroty, and other flooring prodcuts such as raised floor , SPC flooring, Carpet Tiles and Caramic tiles. If you are interested in other flooring products and want to find relevant resources, you can contact AccessFloorStore. Source:

Internet - Preparing your subfloor is mostly a matter of making sure that it is clean, level, and free of any kind of raised or lowered sections, cracks, or imperfections. If there is any old vinyl flooring, carpeting, or other materials on top of your subfloor, remove those first and take off your baseboards (if applicable) temporarily. Note that you should not, under any circumstance, sand down existing vinyl flooring to make it level as older varieties of this material can contain asbestos. Source:

Internet - As you can see, no matter which type of flooring you’ve invested in, the preparations for the subfloor are pretty much the same. Ensuring it’s clean, level and dry enough is the key to ensuring your new floor really lasts the test of time. You’ll find many new floors come with instructions on how to prepare the subfloor to match the new floor’s requirements. Always follow these as closely as you can to ensure best results. Source:

Internet - Wood Plastic Composite (WPC) vinyl flooring and Stone Plastic Composite (SPC) vinyl flooring is the newest innovation in vinyl flooring. WPC and SPC vinyl are more dimensionally stable and usually come in a thickness of over 4mm. For click lock WPC and SPC vinyl flooring, you can install it with a vinyl flooring underlayment, or directly on top of the subfloor. Source:

Internet - Above all, remember the adage to “measure twice and cut once.” You will be amazed at how quickly this process goes as long as you take all of the required measurements and re-check them before making any irreversible decisions. Take your time, and do it right the first time, and your vinyl plank flooring will last you for a very long time. Source:

Internet - Do I need underlayment to install vinyl plank flooring? This is a question we get daily! It is important to know if you need underlayment or not with a vinyl flooring installation. Unlike laminate flooring, most vinyl floors are designed to lay directly on top of the subfloor. The type of vinyl flooring and type of subfloor you have will determine if you are able to use a vinyl flooring underlayment. Source:

Internet - Vinyl flooring is a popular flooring material for homeowners. It’s flexible, easy to clean, and durable. What most people don’t realize is that vinyl floor tiles can be installed over OSB subflooring. Source:

Internet - If it's problem (a), it's really hard to find any click-lock flooring that will seal completely and not let moisture through ANY crack. You just have to be very proactive and fast in mopping up spills or floods. Even a little water sitting for too long can make bubbles happen in cheaper laminate floors or cause cupping in hardwoods or engineered woods. Source:

Internet - The first step is to make sure that your subfloor has been thoroughly cleaned, which is the beginning of preparing subfloors for vinyl. It must be free from any debris and protrusions such as nails to before you can do anything else. A clean subfloor must also be levelled if it is made from concrete or sanded if it is made from wood. Ensuring your subfloor is as clean as possible is not only important for keeping it in good condition, but also to prevent uneven flooring. Source:

Internet - Most vinyl flooring can be installed over electric or hydronic radiant heated floors, with the exception of peel and stick or self-locking (Vinloc) products. Loose lay vinyl flooring will need to be glued down if you have a radiant heated floor. Do not turn heat above 29ºC (84ºF). Source:

Internet - The bond of the flooring to the subfloor is only as good as what you bond to. If you bond to old paint, sealers, polish, or other foreign matter, you are dependent upon the bond of that material to the subfloor to hold the flooring in place. Since we cannot determine how strong that bond may be, it is best to bond directly to the substrate. Source:

Internet - Click lock is just one of the names for vinyl planks that are joined by integrated interlocking tongue-and-groove joints. These planks allow you to create a floating floor, but you don’t need to use an adhesive to attach the planks to the subfloor. Simply snap these planks together to get a reliable and effective fit that will suit many rooms. Source:

Internet - If you exceed the maximum run length for your click or self-locking vinyl, you will need to use transition moulding. For click vinyl only, you also have the option of adhering the vinyl to your subfloor using the “dri-tac” (full spread method). For the “dri-tac” method, apply a high-tack universal flooring adhesive specifically designed for vinyl plank flooring on the subfloor prior to installation. Source:

Internet - If a vapor barrier is not required by code, you need to decide if the subfloor provides protection against moisture. If it’s car decking (tongue-and-groove dimensional lumber) with gaps and knot holes, a vapor barrier is a good idea. Vapor barriers are usually polyethylene sheets (4 mil or thicker) or asphalt-layered kraft paper. Source:

Internet - Because vinyl is made from PVC, it is completely waterproof by itself. However, glue used during installation may decrease the overall imperviousness of the final floor. Also, a large amount of standing water can seep through the seams between the planks or tiles, and damage your subfloor, just like with other types of flooring. For this reason, you should clean up spills as quickly as possible. Source:

Internet - If you find any lowered sections, you can use some of the floor patching compound mentioned earlier in this article to smooth them over. Give the compound approximately twenty minutes to dry, and then sand it down to provide a good texture. Conversely, if there are any raised areas, use a belt sander to bring them in line with the rest of the floor. Lastly, remove any debris from these adjustments, and begin laying your vinyl flooring using the methods listed above. Source:

Internet - One common underlayment for vinyl floors is 1/2-inch particle board. It’s inexpensive, flat, smooth and bonds well to the vinyl adhesives. On the downside, particle board underlayment has very little structural strength. In fact it must be supported by a strong subfloor with limited gaps and it can bridge only small holes. Source:

Internet - Many adhesive removal products contain solvents that leave a residue within the subfloor. This residue can negatively affect the new adhesive and bleed through the new floor covering. Floor covering warranties do not cover instances where existing subfloor conditions cause damage to the flooring or installation failure. Source:

Internet - 2. Measure and cut 1/4-inch or thicker plywood with a circular saw to fit the entire floor of the room where you are installing vinyl flooring. The goal is to have a wooden subfloor consisting of two layers at least 1-inch thick. Source:

Internet - When the time comes to install a new floor, it is common to forget that what you don’t see is just as important as what you do see. In other words, you should think about preparing your subfloor for vinyl before you add any new flooring. The way in which you prepare your subflooring will determine how long your new installation will last. So, keep reading to effectively prep your subfloor! Source:

Internet - There are a few exceptions I make to this floor-break-under-the-door rule. One is in the case of bifold or bypass doors where there is vinyl on one side and carpet on the other. Because bifold doors tend to be a bit higher off the floor and bypass doors do not line up with each other, it’s often preferable to have the floor break on the inside of the closet area where it is unlikely to be seen when the doors are closed. Just imagine the flooring behind the doors peeking out into the living area and you’ll make the right call. Source:

Internet - True expansion joints are those placed between separate pours of concrete. These joints are designed to absorb the movement of the concrete and are normally filled with elastomeric fillers which absorb the movement of the separate pieces of concrete. If an underlayment is placed across or in these joints, the movement of the concrete will cause them to break up or will push them out of the joint. Additionally, any flooring placed across these joints will break with the movement of the concrete. Expansion joint covers, which are designed to span these joints, should be used in these areas. Source:

Internet - Glue down vinyl plank flooring will not need an underlayment. You will install these planks by gluing them directly on top of the subfloor. It is very important to have a debris free and level subfloor for a glue down vinyl flooring installation! Source:

Internet - Many manufacturers make transition strips that match the flooring in color or style. Typically these are supplied with a molding track, a u-shaped piece of metal that can be cut to the desired length and attached to the subfloor for the transition piece to snap into. The doorway should be clear of any material above the subfloor in the threshold where you are installing your transition molding track. If your subfloor is concrete, you will need to use a hammer drill with a masonry bit to install the channel into the doorway. For wood subfloors, this piece can be screwed or nailed into place, and reinforced with a silicone adhesive. Source:

Internet - Vinyl flooring is an option to consider when you need to replace your existing flooring. Some people may wonder whether it is worth putting vinyl floor over OSB. This is because the presence of vinyl creates friction, which can damage your flooring through warping or cracking. Source:

Internet - 1. Cleaning the subfloor before installing plywood underlayment. Debris left on the subfloor can cause problems with the underlayment down the road, such as the void which could allow noticeable movement, floor squeaks or cause fasteners to poke through. Source:

Internet - Whether it is an old wooden floor or new plywood, after completing the above preparations, you can refer to our self-adhesive vinyl floor installation guide to easily complete the laying. If you are looking for a reliable self-adhesive vinyl floor supplier, welcome to send your inquiry to us. Huiya will offer you the high quality and affordable peel and stick vinyl floor and other industrial vinyl floorings for your projects! Source:

Internet - As you know, the installation surface of self-adhesive vinyl must be smooth and flat, otherwise it will seriously affect its normal use. Therefore, before installing self stick vinyl flooring on paywood, we need to ensure that the subfloor is smooth and seamless. Therefore, we need to take the following measures to fix self adhesive vinyl floor tiles on plywood: Source:

Internet - When it comes to vinyl flooring, there are a few options to choose from: vinyl planks or tiles, luxury vinyl planks and vinyl sheets. Each option has unique characteristics and a different method of installation. You can learn more about the different types of vinyl flooring in this previous post. Source:

Internet - Be careful when changing flooring that butts up to a flight of stairs. Building codes allow no more than a 3/8-inch difference between the heights of the lowest and tallest stair risers. Changing the floor height at the top or bottom of stairs will alter riser heights and could create a trip hazard. Source:

Internet - Each of these installation methods is accessible for first-timers and works for any subfloor as long as it flat and inflexible. When choosing the installation style of vinyl planks, consider the kind of room you will be using this flooring in. The GripStrip vinyl planks can be water-resistant as long as they are correctly installed, but the click-lock vinyl plank flooring should be completely water-resistant if you have measured and installed it correctly. Source:

Internet - Test-Fit the First Row of Planks Test fit the first row of vinyl planks down the length of the wall. Visually, the flooring layout will be most pleasing if cut planks are of roughly equal lengths at the opposite side walls. Start with a full plank at the center of the wall and work to either side, so cut planks at the ends will be of equal length. Leave a 1/4-inch gap at the wall and at the ends; spacers can be placed against the walls to establish this expansion gap. The Spruce / Kevin Norris Source:

Internet - 3. Arrange the plywood on the floor so the joints of this layer do not align with the subfloor joints below. Allow 1/4-inch gap along the walls and between the joints for expansion. Secure the plywood to the subfloor at 6-inch intervals with 1-inch deck screws placed along the edges. Set all screw heads slightly below the surface. Source:

Internet - Leave a little room (1/16 inch or so) along fiberglass showers and tubs. Even a little floor flex can cause a squeak where the underlayment rubs these fixtures. If you are installing vinyl flooring in a large area where light from a patio door shines across the surface, it’s a good idea to use carpenter’s glue at the seams between pieces to ensure that they stay well connected to each other as well as to the subfloor. Source:

Internet - Avoid exposure to direct sunlight for prolonged periods of time. Use drapes or blinds to minimize direct sunlight during peak sunlight hours. How do I clean my vinyl flooring? Source:

Internet - These subfloors must meet structural requirements. Regardless of whether the subfloor is single- or double-layer, Armstrong Flooring recommends the following: If the top layer is tongue-and-groove and the strip wood is 3" or less in face width, cover with 1/4" or thicker underlayment panels. All others should be covered with 1/2" or thicker underlayment panels. Source:

Internet - We use a hand brush with stiff bristles around the entire perimeter to rake debris from under the drywall that could cause problems during the install. A thorough sweeping follows. Whoever does the sweeping should watch for nail and screw heads sticking up, as well as holes, large cracks, dry rot and other issues that may warrant subfloor repairs. Source:

Internet - Now that the shoe mold trim is off, use a scrap bit of flooring laid directly on top of the subfloor, and mark the jambs to be cut with a carpenter pencil prior to cutting. This provides a clear line to follow and will help ensure you do not over cut your door jambs. We recommend cutting one and checking it with the product for a clean fit prior to cutting all of your jambs. You should not have to force the floor under the jamb. Always leave about 1/16"-1/8" of breathing room for caulking. Source:

Internet - So the first part of the next step is probably the hardest part: waiting. Whether choosing glue-down or floating type vinyl planks, they should be allowed to acclimate inside of your home for at least 48 hours in the space where they are to be installed. Vinyl planks, along with other types of flooring, can change dimensions slightly depending on the temperature and humidity they are exposed to. Acclimating the product helps keep this material’s natural expansion and contraction from becoming a problem after installation. Source:

Internet - Vinyl flooring packaging will show two thicknesses, one for the total product and one for the wear layer. Total thickness will determine how well the vinyl hides subfloor imperfections and is measured in millimeters (or sometimes inches). The wear layer thickness will determine your floor’s durability and is measured in millimeters or in mil. A 0.5 mm (20 mil) wear layer is usually the minimum required for commercial uses. Source:

Internet - With your transition molding track properly installed, the next thing standing between you and your beautiful new flooring are those pesky door jambs. You want to be able to slide your vinyl plank underneath the door jambs a bit in order to get a seamless installation. If you have any trim work like quarter round or shoe molding, start by carefully removing it from your baseboards. Use a putty knife and a pry bar to get behind the trim and then gently pry it off of the baseboards. Source:

Internet - Really the only think I've seen that can do that is a new solid hardwood system called Easiklip. It's a floating 3/4" hardwood that just sits on top of a standard underlay (i think). It uses a new clip system to attach boards to one another so nothing is ever nailed down. You can actually pop it up again once you've laid it. So in theory, if there's a big flood, you just pull up your flooring, dry up the mess and put it back down again. Source:

Internet - No matter what you lay down, it's going to cost time and money. If you're interested in really the ONLY way to protect that investment...ie in the case of a large floor or really big spill, you really want a system that you can remove without damaging the flooring. That way, in the case of a big moisture problem, you get all the damage prone wood out of there, clean up the mess, and put it all back again. Source:

Internet - There are plenty of reasons to install sheet vinyl flooring, not the least of which is cost savings over other flooring materials. Vinyl flooring is available in a huge number of patterns and colors, is easy to clean and is softer to walk on than most other hard surfaces. Because you can install sheet vinyl over existing vinyl, it offers the option of changing design without breaking the bank. Source:

Internet - SPC flooring can be fitted over a variety of subfloor materials. However, as with other flooring types, you should check for excessive moisture prior to installation. Although they do feature a waterproof design, this tends to only apply to the surface and joints of the floors, rather the bottom of them. If there is an issue with moisture, you can use a moisture barrier underlay for added protection. Source:

Internet - Formaldehyde is a harmful chemical usually associated with laminate and engineered flooring products. It is not a concern with today’s vinyl flooring. All our vinyl products are verified as formaldehyde free. Source:

Internet - Some subfloor materials will soak in water and swell along the edges. Watch for this if your project experienced a lot of rain during the framing stage. The swelling results in ridges where the subfloor sheets come together. These ridges can create noticeable humps and bumps in the underlayment. They can also create voids between the underlayment and the subfloor, which can develop movement, floor squeaks and nail pops later. Source:

Internet - Vinyl flooring consists of PVC – a type of plastic – topped with a decorative paper layer and a wear layer. Some vinyl has a felt backing or is reinforced with fiberglass for greater stability. The wear layer is also treated with aluminum oxide or ceramic bead. A variety of finishes are available that are applied to the top of the vinyl, which makes it look more like real wood or tile. Source:

Internet - If your subfloor is met with too much moisture, it could damage your new flooring once installed. Even though vinyl flooring is usually water-resistant, you don’t want it seeping in from underneath. To prevent this, be sure to install a damp-proof membrane (DPM). This is a common product for most underlays and is suitable for all flooring types. Source:

Internet - As the name would suggest, glue-down vinyl planks use an adhesive to attach the planks to the subfloor. These adhesives come in two varieties, which are either hard-set or pressure-sensitive. Hard-set adhesive is what many people would expect from glued-down flooring in that you spread the glue across the subfloor, and then you lay the planks on top of that. Source:

Internet - In most cases, you can install your vinyl plank directly on top of your plywood subfloor. Most quality vinyl planks come prepared to install directly onto plywood, but if you inherit an older home or have ripped out the previous flooring to get at the subfloor, you may need to take some additional steps. As mentioned in the prior section, your subfloor needs to be at the very least: Source:

Internet - You can install vinyl over wood floors if you put a plywood subfloor on top of it. Do not install glue down or peel and stick products over particleboard, chipboard or any form of embossed floor. Do not install peel and stick products over Lauan (Luan) decorative plywood. Source:

Internet - Inspect the floor and repair cracks, pits, holes, or other uneven patches. Use concrete filler or a similar floor patching compound to repair the damage. If the subfloors have large cracks, then the best course of action is to remove the large part of the slab and replace it with a new one. Source:

Internet - Vinyl flooring is a popular product that can be laid over any type of floor. It is relatively easy to install and has a low life-cycle cost. If you are laying vinyl flooring over OSB, make sure that the OSB doesn’t have imperfections first. Source:

Internet - You can only install your new flooring once you are sure it will be even. This can be done by checking to see if the structure of the subfloor is sound. If your subfloor is made from wood, you can check to see if the plywood sheets are not loose or that they don’t squeak. If you find that some of them are, you will need to screw them into the floor joists to amend this. Source:

Internet - If you are installing your vinyl plank flooring over a concrete subfloor, you may want to use an underlayment for three reasons. First, it will give you some added cushion to help make the floor softer to walk on. Second, you may want an extra vapor barrier above the subfloor to reduce any risk of moisture. Lastly, underlayments can provide thermal properties to help keep the flooring warmer in cold months. Source:

Internet - The vinyl flooring will conform to the rolling nature of the floor to a better degree than most other flooring types and if you don't mind it being a little bouncy in some places I suspect it isn't worth the effort to do anything more than ensure there are no squeaks, there are no large holes and the floor is within the 1/2" difference over 4'. The floor really just needs to be flat not level and pretty much the only case where I'd go to effort/money to flood a floor with self level is if that room receives no furniture and no area rugs. If you already know the areas where furniture will sit you can spend more time on the areas where someone is likely to walk and notice the bounce / dipping of the floor. Source:

Internet - Before you do anything else, you should measure and prepare your subfloor for installation. Take exact measurements of the room to ensure that you know how much vinyl plank flooring you need, and then purchase an additional 10-20% additional flooring. The reason for the extra planks is that you will guarantee that you have enough to floor the entire room while maintaining excess stock if you need to cut any planks or replace parts of your floor in the future. Source:

Internet - Luxury vinyl flooring is known to be extremely durable. However, that doesn’t mean you can get away with a poor-quality subfloor. Even vinyl floors can become damaged over time when exposed to moisture. So, you’ll still need to check the moisture levels of the subfloor prior to installation. Source:

Internet - When it comes to laminate flooring, there are certain types of subfloors which aren’t suitable to use. These include cushioned flooring, carpets and glued vinyl. Ideally, you’ll want to work with a concrete, plywood, ceramic or vinyl subfloors which hasn’t been glued down. Source:

Internet - This is a wood subfloor installed over an existing concrete subfloor without 18" of well ventilated air space below. Concrete on or below grade will have some moisture in it due to its proximity to the ground. When there is not enough ventilation, moisture will build up causing not only installation failure, but possible rotting of the wood. Suspended grade subfloors that are not sufficiently dry can experience the the same problems. Source:

Internet - You’re also going to want to check the moisture levels. If there is any moisture in the subfloor, it’s going to cause issues with warping and swelling in your floor over time. This can lead to irreversible damage which will be costly to replace. If there is high moisture, consider investing in a moisture-resistant underlay to help protect your new floor. Source:

Internet - Peel and Stick Vinyl Floor Tiles (Self-Adhesive Vinyl Planks) is becoming increasingly popular as a material for flooring. Because of its properties, it is used in many areas. Of course, you can also lay self-stick vinyl planks on wooden floors. However, there are some important points to note. Here we will guide you to properly apply peel and stick vinyl floor tiles on plywood, teaching you how to prepare the floor to put down self-adhesive vinyl planks to wood subfloors. Source:

Internet - Vinyl floors can be installed on top of wood subfloors; however, they’re not recommended for use on top of concrete or tile floors. A vinyl floor can be used for a variety of purposes. There are even some companies that use vinyl flooring for their offices and warehouses. Source:

Internet - Whenever practical, run the long direction of the underlayment sheets in the opposite direction of the subfloor material so they cross each other. This adds to the floor’s structural strength. Avoid placing sheets of underlayment in such a way that the seams of the underlayment correspond or line up with the joints in the subfloor. Source:

Internet - Some put vinyl flooring over OSB, believing that the material is fire retardant. However, this is not true. Vinyl can burn just as easily as wood and should be treated differently than other flooring materials. Source:

Internet - When fitting wood flooring such as an engineered wood or solid wood floor it is important to ensure the subfloor is moisture free. After removing your old floor, you’ll typically be left with either a plywood or a concrete subfloor. It’s vital the subfloor is prepared accordingly if you want your hardwood floor to last. Source:

Internet - Plywood is a common underlayment, with better structural strength and water resistance than particleboard. Plywood used as an underlayment for peel and stick vinyl flooring should have a sanded, smooth surface on the topside. Avoid using materials with distinct raised grain patterns and voids, which can affect the finish adhesion of the self-adhesive vinyl. Source:

Internet - It is also important for you to know the thickness of the subfloor. This is because the thicker it is, the more stable it will be. It is best to have subflooring that is no thinner than 20mm Source:

Internet - Fit Planks Around Protrusions After making the cutouts, first attach the plank to the adjoining plank while holding the cut-out plank upward, at an angle. Then slowly fold down the cut-out plank until it locks into place with the adjoining plank. Vinyl plank flooring is flexible enough that it can usually be bent enough to fit around door frames and other protrusions. Depending on the nature of the obstruction, it may be necessary to disassemble previous planks in order to navigate the cutout plank into position. The Spruce / Kevin Norris Source:

Internet

Here are some recommendations for locating information about Osb Underlayment For Vinyl Plank to get you started: - Research preparing subfloor for luxury vinyl plank flooring-related information from credible sources. This includes libraries, websites, and even journalistic professionals. - When researching Preparing Concrete Subfloor For Vinyl Plank Flooring, it is vital to be aware of the numerous sorts of electronic media sources, such as Google and YouTube. Social media networks, such as Facebook and Twitter, are also likely to include information on Install Vinyl Flooring Over Plywood Subfloor.

# Video | Vinyl Plank Flooring Subfloor Prep

To obtain the most accurate information on preparing subfloor for luxury vinyl plank flooring, it is essential to investigate the credibility of each source by reading.

This page contains multiple Underlayment For Vinyl Plank Flooring-related films from a variety of sources, which can expand your understanding about preparing osb subfloor for vinyl plank flooring. Internet is an excellent resource for getting information on a range of subjects.

Here are some crucial aspects concerning Underlayment For Vinyl Plank Flooring:

- vinyl plank flooring subfloor prep

- prepare subfloor for vinyl plank flooring

- preparing subfloor for vinyl plank flooring

- preparing osb subfloor for vinyl plank flooring

- preparing wood subfloor for vinyl plank flooring

With so many websites and forums giving Do I need underlayment to install vinyl plank flooring?-related information, it is not difficult to locate what you want.

This is a highly unconventional method for obtaining knowledge on How To Level Plywood Subfloor For Vinyl Plank, compared to what most people are accustomed to. It permits a more in-depth examination of the content and application of information regarding DIY Guide: How to Install a Floating Vinyl Floor.

# Images | Vinyl Plank Flooring Subfloor Prep - Can/Should You and How to Install Vinyl Plank on Plywood

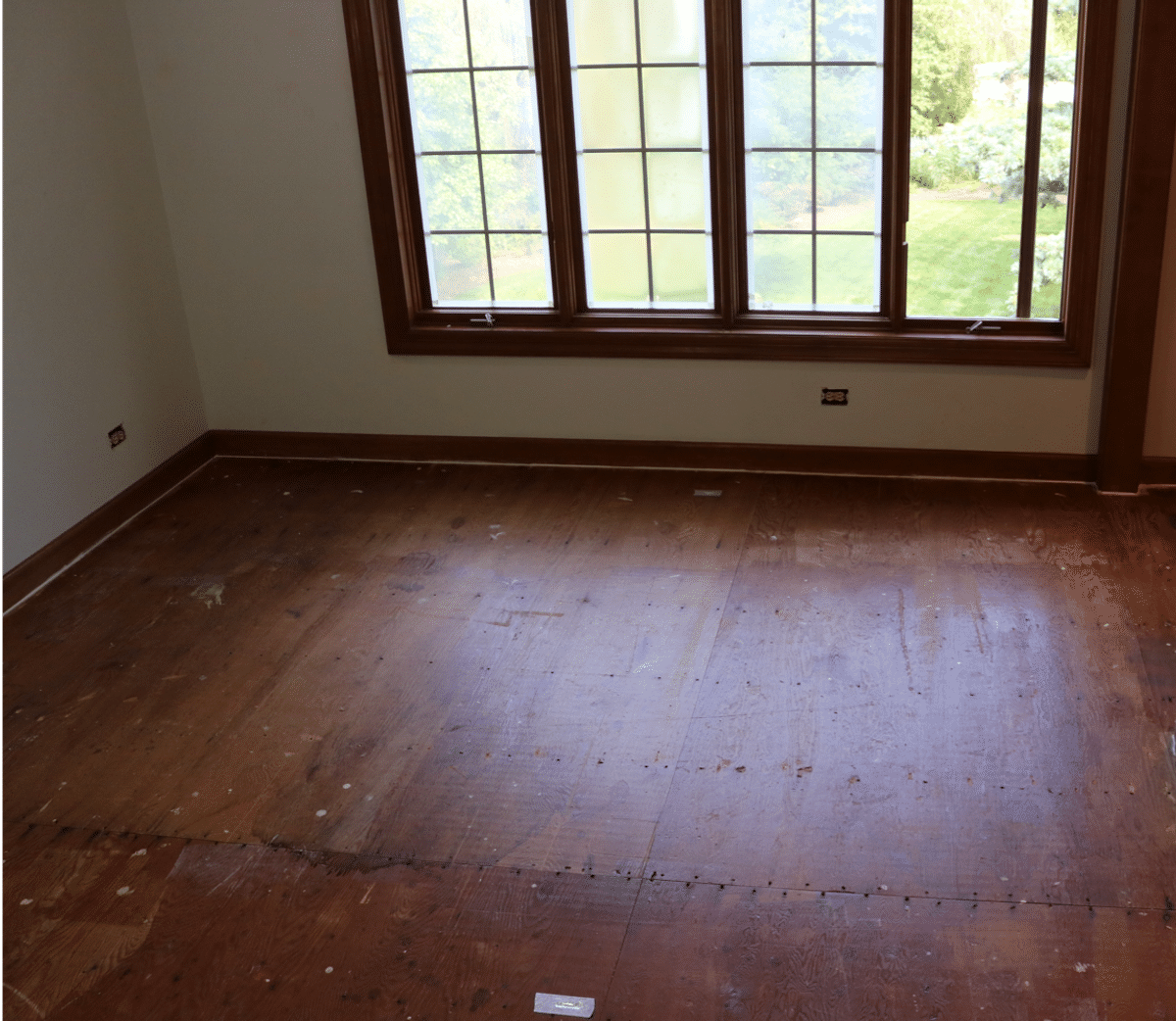

Install Vinyl Flooring Over Plywood Subfloor - Can/Should You and How to Install Vinyl Plank on Plywood

Save

Save

How Flat Does Subfloor Need To Be For Vinyl Plank - Installing Floating Vinyl Plank Flooring Over Osb

Save

Save

Methods for creating aesthetically pleasing and informative presentations of Install Vinyl Flooring Over Plywood Subfloor information. They can be utilized in business and marketing environments to convey messages regarding How To Level Plywood Subfloor For Vinyl Plank. Consequently, we additionally supply photographs regarding Can/Should You and How to Install Vinyl Plank on Plywood.

This article concludes by providing an overview of Preparing Concrete Subfloor For Vinyl Plank Flooring. In addition, DIY Guide: How to Install a Floating Vinyl Floor and Preparing Concrete Subfloor For Vinyl Plank Flooring are discussed to compare your understanding of Do I need underlayment to install vinyl plank flooring?.

Reference:

https://factfamilystock.blogspot.com/2022/11/54-about-wide-plank-light-oak.html

0 comments